Ensure our ultrasonic cleaner with durable quality and good performance we have strict testing procedure during develop and mass production.

Quality Control

Ensure our ultrasonic cleaner with durable quality and good performance we have strict testing procedure during develop and mass production.

01 Ultrasonic Power Test

Ultrasonic cleaning machine is a device that uses high-frequency mechanical waves generated by ultrasonic waves to separate, decompose, and remove stains through liquid media, in order to achieve the purpose of cleaning. ultrasonic power is a very important performance parameter, and different powers will affect the cleaning effect

02 Ultrasonic Sound Intesity Test

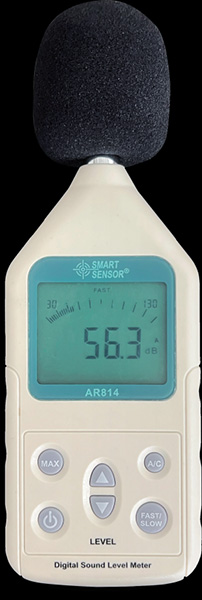

The cleaning effect of the ultrasonic machine is directly proportional to the intensity of the sound wave signal.The Sound intensity tester

Will be amplified and filtered through tester sensor,Detect the energy changes of sound waves and convert them into electrical signals to calculate the sound

Wave intensity value. Based on this, the relevant parameters of the cleaning machine can be evaluated and adjusted to achieve better cleaning effect.

03 Clean Penetration Test

A method for testing the performance of ultrasonic cleaning machine with aluminum foil, Place multiple aluminum foils at different angles in the cleaning tank of the ultrasonic cleaning machine, the washing tank is filled with cleaning solution, and the ultrasonic waves generated by the transducer over a certain period of time are used to

Aluminum foil undergoes cavitation corrosion; Image analysis of aluminum foil after cavitation corrosion, through

The corrosion area ratio of aluminum foil is used to evaluate the cavitation intensity of ultrasonic waves

The larger the cavitation, the stronger the cavitation intensity will evaluate the uniformity of corrosion pore distribution in aluminum foil

The distribution of ultrasonic intensity, the smaller the uniformity of corrosion pore distribution, the more ultrasonic waves the more uniform the distribution of intensity.

04 Hi-Low Temperture Cycle Test

High and low temperature cycling tests can evaluate the performance of products, in extreme temperature environments ensure that the product can operate stably during storage, transportation, and use avoiding temperature related issues Performance degradation or damage caused by changes in temperature. This is important for improving product quality and extending the lifespan.

The lifespan and ensuring user safety are great significance.

05 Product Tensile Test

Product tensile testing is a mandatory testing method, tensile testing should be supplemented by rupture testing and ensures the quality of sealing , which includes static tensile testing and dynamic tensile testing.

06 Product Noice Test

Ultrasonic probe tester is a commonly non-contact testing device, typically used to measure surface defects of objects and internal defects in materials. In addition, ultrasonic probes can also be used for noise test; The principle, steps, and application scope of ultrasonic probe noise depend on the processed noise signal to analyze the state of the material to be tested, such as whether there are defects, damages, etc., and provide corresponding judgment results. Ultrasonic probe noise testing is a very effective detection method, it is high efficiency, high precision, and high reliability.

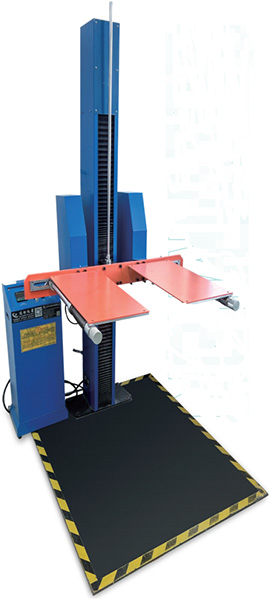

07 Drop Test

Drop testing is an important method for evaluating the durability and quality of products, mainly used to simulate the possible drop situations that products may encounter during transportation, usage, in order to test th e impact resistance of products., the durability of the product can be evaluated.

08 Temperature and Humility Test

The principle of monitoring temperature and humidity is measured by temperature sensors and humidity sensors.

The temperature and humidity levels of the environment are used to provide accurate environmental data, as result to test the product ability for anti- temperature &anti-humility.

09 Salt Spray Test

Salt spray test is an environmental test primarily used to evaluate the corrosion resistance of materials or products. The experiment uses specific equipment to create a salt spray environment, simulating harsh conditions such as high salt and high humidity in marine, coastal, and industrial pollution areas. The experimental equipment sprays a mist containing a certain concentration of salt (usually sodium chloride solution) onto the surface of the tested sample, and after a period of time, test the ability of surface anit- rusting,anti- corrosion, andanti-coating peeling.

10 Simulate Transport Vibration Test

Use a simulated transportation vibration table is a device used to simulate the vibration environment during transportation. The product movement during the movement of transportation vehicles trucks, trains, airplanes, etc. By precise control programs, parameters such as frequency, amplitude, acceleration, etc. of vibration can be adjusted. helping test the product's tolerance during transportation

Let our team help you select the right product.

Talk to our experts and we can help you meet all template requirements from scratch. Let us provide assistance for your next project.

Partnerships

We are working with

Our Knowledgeable Team is Here to Help

1. Industrial Cleaning; 2. Laboratory Cleaning and General Equipment; 3. Gene Transduction; 4. High-Throughput Screening; 5. Fermentation Optimization; 6. Sample Pretreatment; 7. Separation and Purification; 8. Sample Preparation

Customize NowNews&Events