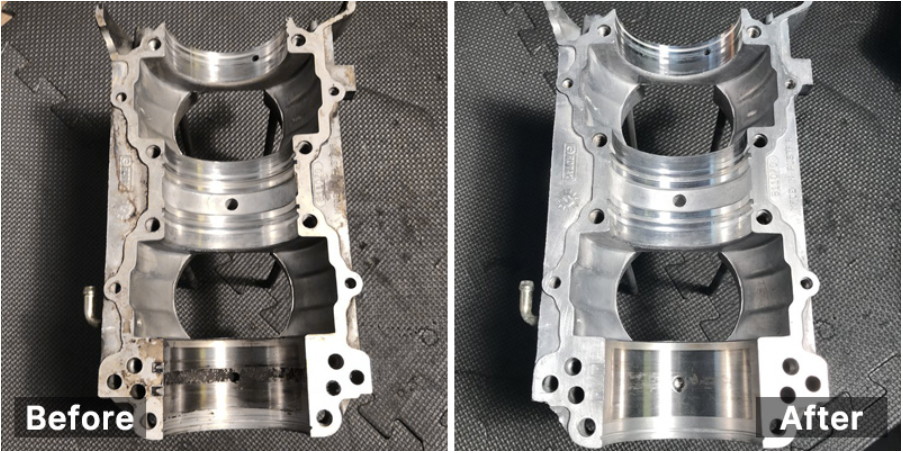

Engineered for industrial versatility, this multi-chamber ultrasonic cleaning system revolutionizes surface preparation with customizable modes (cleaning/degreasing/drying/filtration) and precision engineering.

Its high-frequency cavitation technology (28-40kHz+) creates microbubbles that penetrate intricate geometries, efficiently dissolving stubborn contaminants including industrial lubricants, metal oxides, and microparticles.

Crafted with corrosion-resistant SUS304 stainless steel, the unit withstands aggressive chemicals and extreme temperatures up to 150℃ while optimizing energy efficiency through smart thermal management.

Ideal for critical applications across aerospace, precision electronics, medical device manufacturing, and automotive sectors. Features adjustable frequency settings (gentle 40kHz+ for delicate instruments) and holds multiple international certifications (CE/ROHS/FCC) ensuring compliance with rigorous quality standards.